Improved scalability and purity of AAV8 processes, providing high-quality material and accelerating clients’ path towards successful clinical trials.

Case Studies

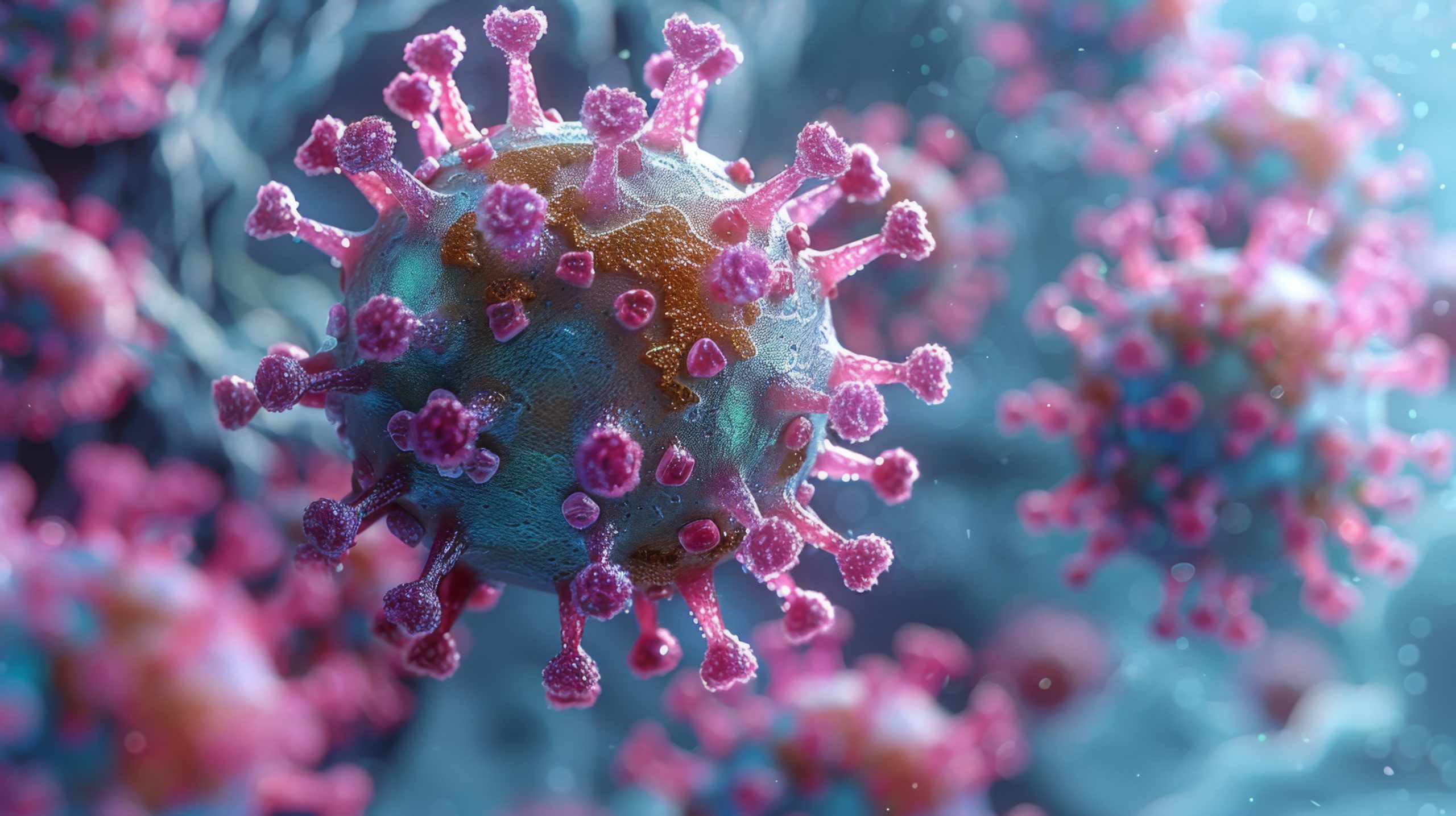

Optimising AAV8 Manufacturing for Preclinical Success

The Challenge: Scalable, High-Quality Manufacturing

AAV8 gene therapy developers often face significant hurdles in scaling academic processes for clinical readiness. Challenges include low process yields and complex impurity profiles that, without significant optimisation, can impact the delivery of suitable material for preclinical and toxicology studies, resulting in delays to clinical programs.

Our Approach

Over the past decade, eXmoor Pharma has partnered with multiple clients to deliver AAV8 material generation projects alongside full process and analytical development packages. By maintaining close collaboration throughout, from technology transfer to final deliverables, eXmoor Pharma applied its deep expertise in AAV manufacturing process design to optimise performance and ensure scalability.

Execution

The Outcome

Deliverables & Impact

eXmoor Pharma delivered an improved, scalable manufacturing process for AAV8, alongside high-quality materials required for preclinical development.

This enabled clients to progress confidently towards clinical trials with a robust and compliant process.

Case Studies

See how eXmoor Pharma has helped biotech innovators scale their therapies with precision and efficiency.

Enhancing Lentivirus Stability for Clinical Progression

Resolved lentivirus stability challenges, securing regulatory approval and progression into Phase 2 clinical trials for a US biopharma client.

Optimising iPSC Manufacturing for Clinical Success

Transformed academic iPSC processes into GMP-ready clinical manufacturing strategies, overcoming significant scalability and regulatory hurdles for innovative cell therapy development.

Let’s Accelerate Your Therapy Together

Whether you’re in early-stage development or scaling up for commercial production, eXmoor Pharma provides the expertise and flexibility you need. Partner with us to move your therapy forward with confidence.