Successfully converted adherent iPSC cultures to scalable suspension systems, enabling GMP-compliant clinical manufacturing and commercial scale-up readiness.

Case Studies

Translating iPSC Processes for Scalable GMP Manufacturing

The Challenge: Transitioning from Adherent to Suspension Culture

A European biotech client required support to translate their adherent iPSC culture into a suspension-based system, aiming for efficient scale-up and GMP-compliant clinical manufacturing.

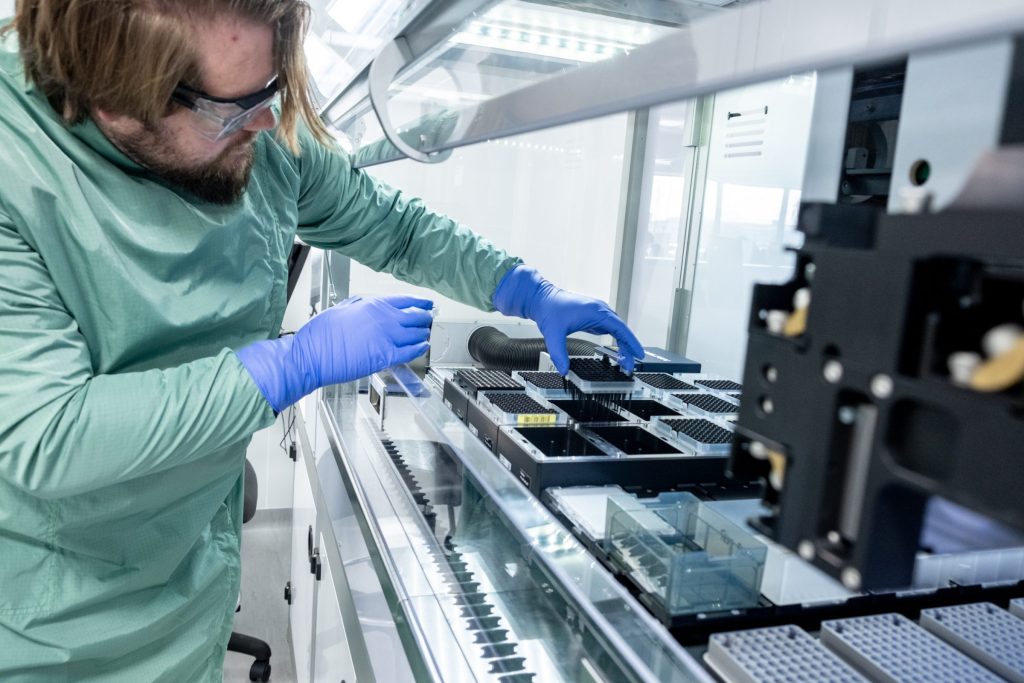

Our Approach

We collaborated closely with the client, performing comprehensive assessments in eXmoor Pharma’s process development laboratories, including GMP media screening, stirred tank evaluation, optimisation of culture conditions (e.g., dissolved oxygen, agitation), harvest, and cryopreservation protocols using Design of Experiments (DoE).

Deliverables

The Outcome

Impact

Our process translation and optimisation enabled the client to confidently progress towards larger-scale GMP manufacturing, laying critical groundwork for future clinical production and commercial scalability.

Case Studies

See how eXmoor Pharma has helped biotech innovators scale their therapies with precision and efficiency.

Optimising AAV8 Manufacturing for Preclinical Success

Improved scalability and purity of AAV8 processes, providing high-quality material and accelerating clients’ path towards successful clinical trials.

Supporting Commercial Scale-up and Technology Transfer

Delivered strategic project management and seamless technology transfer, empowering TxCell’s commercial manufacturing scalability and operational success.

Let’s Accelerate Your Therapy Together

Whether you’re in early-stage development or scaling up for commercial production, eXmoor Pharma provides the expertise and flexibility you need. Partner with us to move your therapy forward with confidence.